The Impact of Dry Ice Blasting on Industrial Maintenance and Beyond

In today’s rapidly evolving industrial landscape, traditional cleaning methods are being pushed to their limits. Many industries face growing demands for faster, safer, and more environmentally responsible cleaning solutions. Dry ice blasting has emerged as a powerful alternative that meets these modern requirements with remarkable efficiency and care.

This innovative cleaning technology uses solid carbon dioxide pellets accelerated at high speeds to remove contaminants without damaging surfaces or producing hazardous waste. As companies seek to reduce downtime, improve worker safety, and adopt greener practices, dry ice blasting is quickly becoming a go-to solution across various sectors.

What Is Dry Ice Blasting and How Does It Work?

Dry ice blasting involves propelling frozen carbon dioxide pellets through a pressurized air stream onto a contaminated surface. Upon impact, the pellets create three effects simultaneously: mechanical abrasion from the kinetic energy, thermal shock caused by the extreme cold, and sublimation of the dry ice from solid directly to gas.

The rapid cooling causes contaminants to contract and become brittle, breaking their bond with the surface. The mechanical force dislodges the debris, which can then be wiped or brushed away. Because the dry ice sublimates instantly, no secondary media or residue remains, eliminating any additional cleanup efforts.

Advantages Compared to Conventional Cleaning Methods

Traditional cleaning approaches such as abrasive blasting, chemical solvents, and high-pressure water washing often have significant downsides. These can include surface damage, chemical hazards, water contamination, and long equipment downtime.

Dry ice blasting offers several critical advantages:

- Non-abrasive: It cleans thoroughly without scratching or wearing down delicate equipment and surfaces.

- No secondary waste: Unlike sand or plastic bead blasting, no blasting media residue is left behind.

- Chemical-free: It requires no solvents or detergents, ideal for sensitive or hygienic environments.

- Minimal downtime: In many cases, equipment can be cleaned in place without disassembly or extended shutdowns.

These benefits lead to safer work environments, reduced maintenance costs, and less environmental impact.

Applications Across Industries

Dry ice blasting’s versatility allows it to serve many fields effectively:

Food Processing and Packaging

Hygiene is paramount in food production. Dry ice blasting cleans ovens, conveyors, mixers, and packaging lines without introducing moisture or chemicals. This reduces the risk of microbial growth and contamination, helping companies meet strict food safety regulations.

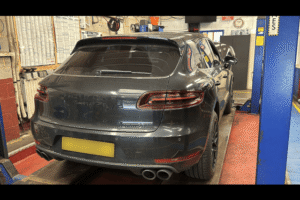

Aerospace and Automotive

Precision and care are vital when cleaning engines, molds, and machinery in aerospace and automotive manufacturing. Dry ice blasting removes grease, paint, and carbon deposits without damaging sensitive parts, maintaining performance and reliability.

Electronics Manufacturing

Delicate electronic components and circuit boards require moisture-free cleaning to avoid corrosion or electrical damage. Dry ice blasting cleans these parts gently and effectively without water or abrasives.

Restoration and Remediation

Fire and smoke damage restoration teams rely on dry ice blasting to remove soot and charred residues from wood, brick, and stone without further damage. Mold remediation also benefits from this dry, non-toxic cleaning method that does not promote regrowth.

Historic Preservation

Cleaning historic monuments and sculptures requires methods that don’t erode or discolor surfaces. Dry ice blasting provides a gentle yet effective option for removing graffiti, pollutants, and biological growth without harming the original materials.

Environmental and Safety Considerations

Sustainability is a major driver behind the adoption of dry ice blasting. The carbon dioxide used is often reclaimed from other industrial processes, so the method does not introduce new greenhouse gases. It also avoids water use and chemical discharge, eliminating wastewater concerns.

From a safety perspective, dry ice blasting reduces worker exposure to hazardous chemicals and eliminates the slip hazards of wet cleaning methods. However, it requires proper ventilation because sublimation releases CO₂ gas, which can displace oxygen in enclosed spaces.

Practical Limitations and Operational Challenges

Despite its many advantages, dry ice blasting is not a universal solution. It is less effective at removing extremely thick coatings, hardened rust, or cement without prior mechanical removal. The initial investment in equipment and consumables can be significant, and operators need specialized training to use the technology safely and effectively.

Storage and handling of dry ice require insulated containers to prevent sublimation losses, and proper safety protocols must be followed to avoid asphyxiation risks in confined areas.

The Future Outlook: Cleaner, Safer, and More Efficient

As companies worldwide face tighter regulations and increasing pressure to reduce environmental impacts, dry ice blasting offers a promising way forward. It combines efficiency, surface safety, and sustainability in a cleaning method that minimizes downtime and operational costs.

By enabling in-place cleaning, reducing hazardous waste, and preserving equipment integrity, dry ice blasting helps industries operate more smoothly and responsibly. Its expanding adoption in food processing, aerospace, automotive, restoration, and beyond signals a shift towards smarter, greener maintenance technologies.

In conclusion, dry ice blasting is more than just a cleaning technique—it’s a transformative tool that enhances productivity, protects workers, and supports environmental stewardship. As industries continue to innovate, this technology will play an increasingly important role in maintaining the high standards required for modern operations.